Spray Nozzles for Continuous Casting Cooling

Sealpump, Spray Technology Experts

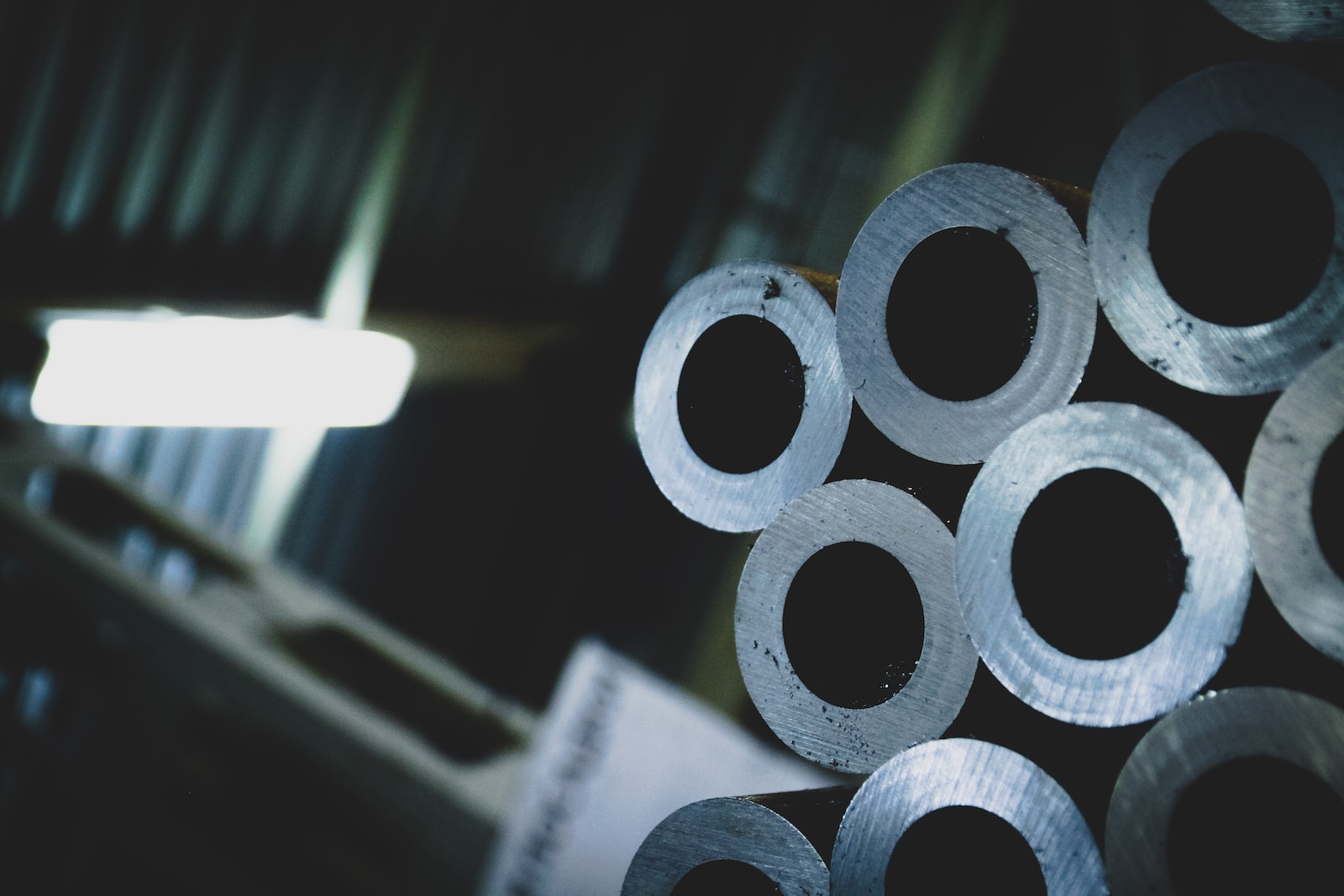

Spray Nozzles for Continuous Casting Cooling

Slabs, blooms and billets are often cooled using water, ensuring quality spray nozzles are installed within the spray segment chambers will maximise the cooling efficiency and even cooling across the product.

Sealpump engineering offer quality airmist spray technology and hydraulic spray nozzles. Airmist spray technology offers a uniform distribution, fine atomisation combined with good impact. Hydraulic nozzlesHydraulic nozzles are devices that use fluid pressure to break up liquids in... ...click for more are used in top zones of slab casting machines, and throughout billet cooling zones, the increased contact area of the spray helps minimise temperature gradients, a contributing factor in crack formation in the steel.

Sealpump sales engineers will assist in helping size the correct solutions and offer competitive pricing and availability, please contact our office for further details.

For Technical Information and Specifications,

download our PDF