Steel Industry Nozzles and Their Applications

With over 30 years experience, we offer a complete range of spray nozzles and spraying systems for use in steel mills, with processes ranging from cooling of slabs, blooms and billets to the cooling, cleaning and rinsing of steel and strip. We also have nozzles for roll cooling, nozzles for rinsing and cooling in pickling lines, nozzles for quenching and cooling in coke plants and nozzles for liquor flushing. In addition we have nozzles and systems for dust and pollution control.

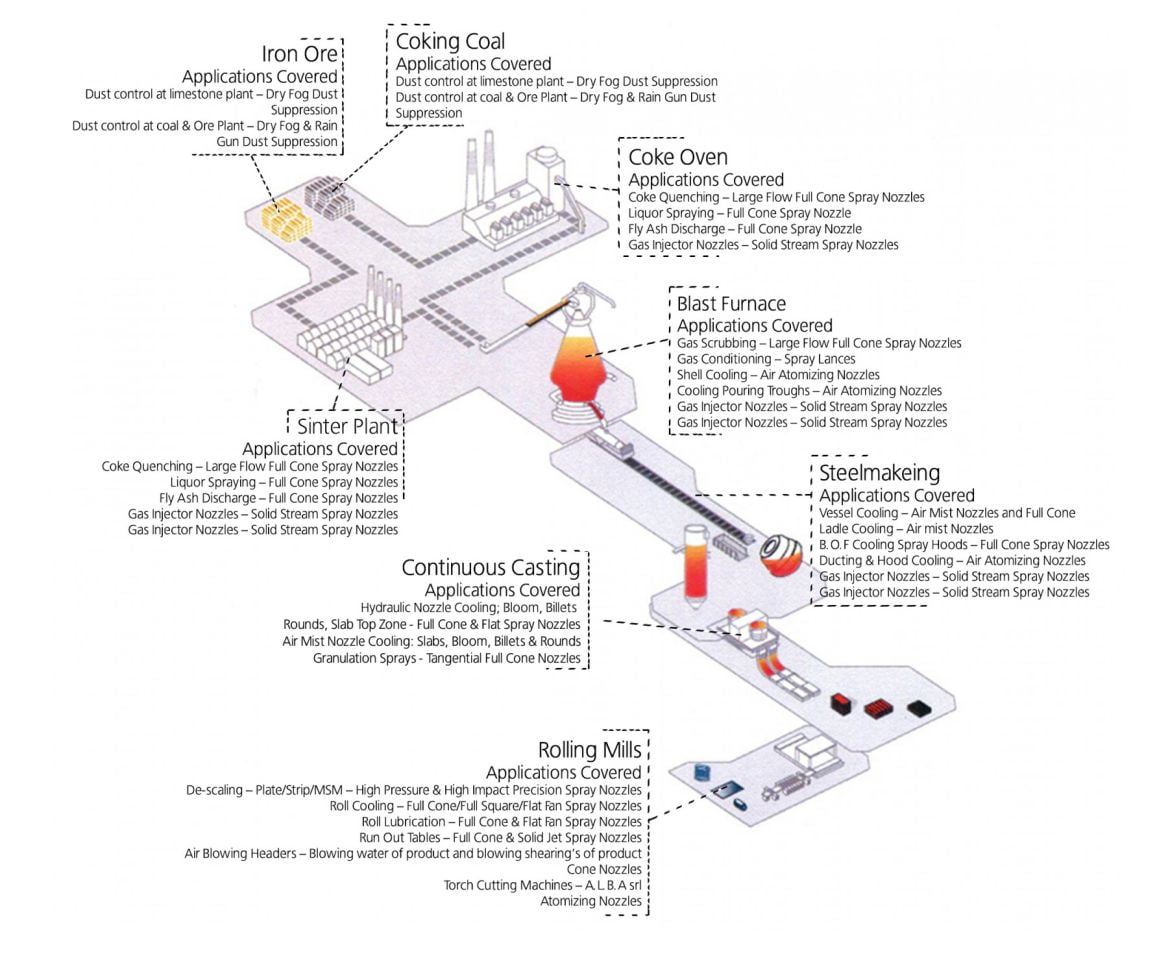

Below we show a flow line of the steel making process and areas that benefit from quality spray nozzle products.

Applications

Continuous Casting

Secondary Cooling

Features

Highly uniformed distribution

Highly uniform droplet size

Even cooling characteristics

Wide passages prevent blockage

Large turn down ratio

Fluid orifice can be removed and cleaned/replaced without removing nozzle assembly

Applications

Continuous Casting

Secondary Cooling

Features

Removable circlip to allow for easy cleaning and maintenance

Even Distribution

Brass construction with stainless steel circlip and locating pin

Working pressure between 2 – 20 bar

Brass retaining nut

Applications

Continuous Casting

Secondary Cooling

Features

One piece body with internal core

Full cone spray pattern

Even distribution

Male or female connections

3/8″ BSP Threaded

Applications

Roll Cooling

Features

Produces a uniform, flat spray without hard edges

Tapered edges of pattern allow overlapping for even distribution

Orifice is offset 15 degree to axis of dovetail

Dovetail connection for consistent alignment

Applications

Continuous Casting

Secondary Cooling

Features

Removable circlip to allow for easy cleaning and maintenance

Even Distribution

Brass construction with stainless steel circlip and locating pin

Working pressure between 2 – 20 bar

Brass retaining nut