How The Automatic Spray System Works

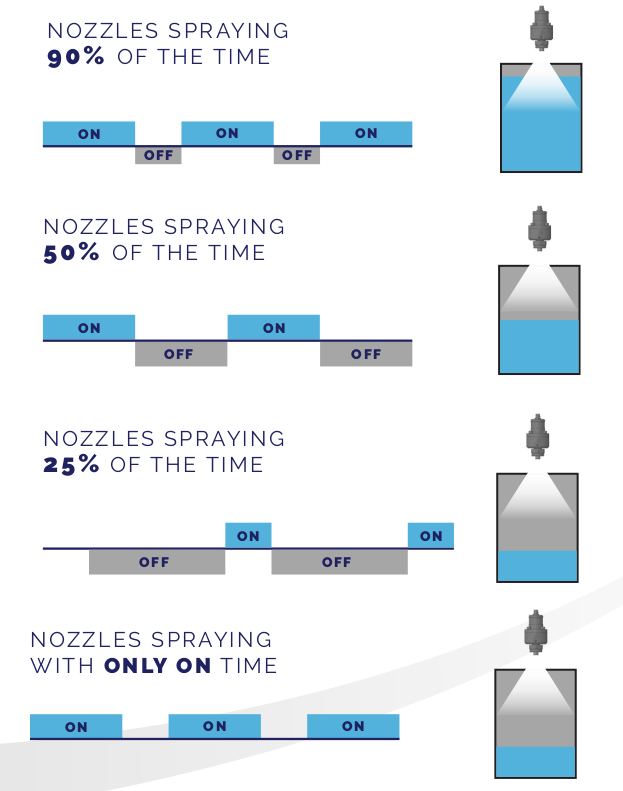

The electrically actuated pulse spray system and nozzles have an internal solenoid valve mounted virtually next to the nozzle tip itself. This electrically actuated valve allows the nozzle to be turned on and off extremely quickly giving exact control over the flow rate produced but without altering the pressure as is the case with standard hydraulic and pneumatic atomising sprays.

By being able to control the flow rate through controlling the pulse cycle, lower flow rates can be achieved and importantly without compromising the spray performance, so the angle and droplet size can remain the same while the flow adjusts for different line speeds or product application rates for example.

It can be used at high speeds and so can be used on high speed production lines. Pressure can remain constant as the flow can be adjusted by simply altering the spray pulse cycle.

This method of control also greatly reduces the misting and overspray that is often seen in low flow atomising systems. This helps with material usage control, improves system and process cleanliness and can have employee health benefits, especially when spraying oils and glazes.